Reducing Lead Exposure

from LSL Replacement

|

|

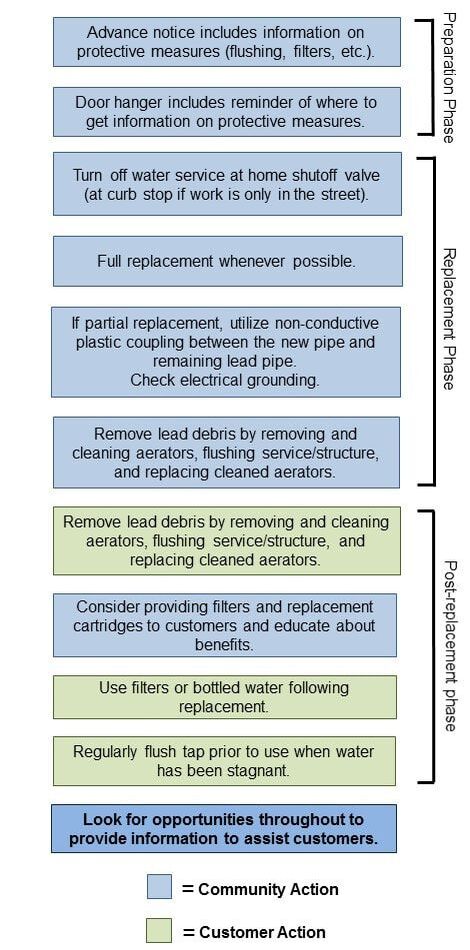

Protective measures to minimize lead exposure

|

Flushing

Flushing the new service line upon installation (construction crew): After all connections have been completed, flush the water from an outside connection (such as hose-bib or hose leading from the house side of the meter installation) to remove any particles in the service line and near point-of-entry. The flushing is best done, if possible and practical, before the meter is connected in the service using a “jumper” or straight pipe in place of the meter. Flush at full velocity for 10 minutes.

Flushing of home plumbing after lead service line replacement (resident): The customer should flush all interior premise plumbing the same day or before next water use following the replacement. Subsequent flushing by the customer should be done once every two weeks for three months or at other intervals based on monitoring results if available.

Flushing of home plumbing after lead service line replacement (resident): The customer should flush all interior premise plumbing the same day or before next water use following the replacement. Subsequent flushing by the customer should be done once every two weeks for three months or at other intervals based on monitoring results if available.

Additional Resources:

- Video: Whole House High Velocity Flushing Protocol

- Fact Sheet: How to flush your indoor plumbing (NY State Department of Health)

- Fact Sheet: After Lead Service Line Replacement (Denver Water)

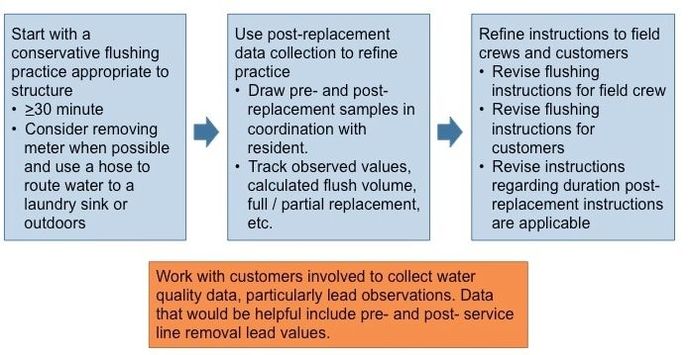

Determining how long to flush a structureAWWA prepared an internationally recognized standard practice for lead service line replacement and flushing (ANSI/AWWA C810-17). EPA has referenced this standard but there is not formal federal guidance on flushing a service line after a full LSL replacement.

In addition to the elements described above, the following steps can be taken to ensure adequate flushing:

|

To avoid introducing lead debris into the home plumbing during post-construction flushing:

Occupants should also consider using filters meeting ANSI/NSF 53 certification for lead removal after an LSL replacement. |

Available data is largely from partial LSL replacements and often from systems that are experiencing difficulty maintaining corrosion control. While lead levels in a home’s water may not be lower initially following replacement of the entire service line due to other existing sources of lead, the service line and replacement process is expected to contribute less lead over time than a partial LSL replacement.

|

Research is ongoing. A Water Research Foundation report “Evaluation of Flushing to Reduce Lead Levels” evaluated the impact of high-velocity flushing on the removal of particulate lead from service lines and premise plumbing, and the subsequent impact on "at the tap" lead concentrations. The research was published in 2018 and includes guidance to utilities on how to perform in-home tap flushing following a service line disturbance (partial or full replacement). An ongoing study “Full Lead Service Line Replacement Guidance” will provide additional data on strategies to reduce lead exposure after conducting full lead service line replacements. This study is expected to be completed in 2020.

Clearing the service line by flushing cold water through it removes debris after construction. Clearing the line requires moving water rapidly, which typically involves turning multiple faucets. It is useful to turn on faucets designed for larger flow rates, like bathtubs. Aerators should be removed and cleaned if possible. |

Convincing occupants to commit the time requested to completely flush a service line can be challenging. In particular, flushing in drought-impacted areas or communities who are sensitive to the cost of water, “wasting” water can be difficult to communicate.” Providing suggestions on ways to capture and use water from flushing can facilitate household acceptance.

Additional information about service line flushing:

Additional information about service line flushing:

The following flowchart illustrates proper protocol for utilities for flushing a service line.

Flushing a Structure

Non-conductive plastic couplings

Non-conductive plastic couplings are used to provide a water tight connection between two pieces of pipe made of different metals without letting the two metal pipes touch. This prevents accelerated corrosion and deterioration in the piping system due to galvanic corrosion. When replacing an LSL, a connection between copper replacement pipe and residual pieces of lead pipe or galvanized pipe can reduce lead release.

Warning:

Non-conductive couplings will only work correctly if properly installed.

Non-conductive couplings will only work correctly if properly installed.

|

If the LSL is replaced with a non-metallic pipe or a non-conductive plastic coupling is used within a few feet of the home, the home owner may need to take additional measures to ensure the structure has sufficient grounding. Historically, connection to the home piping system was used for grounding the home’s electrical system. By removing the underground metal piping, an alternative grounding strategy may be needed.

All metal water systems should be “bonded.” Failure to adequately bond the potable water piping systems to the electrical system increases the potential for both fire and electrocution should the piping system become energized (see National Electric Code). Contact a licensed electrician or building inspector for information about applicable electric code requirements and why they are important. |